SPLat lowers OEM costs with HMI430—an integrated PLC with 4.3-inch touchscreen

HMI430 with MultiTrack™ simplifies controller programming for small- and medium-sized businesses needing touchscreen-based products

Melbourne, Australia – Oct. 28, 2014 – SPLat Controls announces the HMI430 board-level programmable logic controller (PLC) with an integrated 4.3-inch colour touchscreen, available at nearly half the cost of previous products with similar functionality. With onboard, ruggedized digital I/O, analog I/O, and the SPLat MultiTrack™ built-in multitasking operating system, the HMI430 delivers professional-quality control that is affordable and easy to program, minimizing development time.

HMI430—Designed and priced for integration

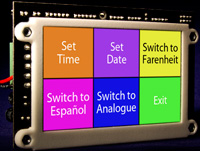

With multiple serial ports HMI430 offers OEMs an ideal way to flexibly integrate a touchscreen into their solution for small- and medium-sized

industrial control applications. The touchscreen—a 4.3-inch 470x272 pixel screen with resistive touch and 64K colours—comes with a repertoire of

standard buttons, fonts, and other screen elements. With support for alpha blending, image files, and Z-ordering, HMI430 offers sophisticated

visual effects at a price point that OEMs can afford.

“With the advent of smartphones, all controller applications—medical, industrial, building control—are affected by the end-customers’ expectation of a GUI-driven interface,” noted David Stonier-Gibson, CEO of SPLat Controls. “The HMI430 with an integrated colour touchscreen enables OEMs to respond to this ‘iEffect’ and provides the innovative edge that helps small- and medium-sized equipment manufacturers make their products smarter and more competitive.”

Geared to address a wide range of control applications, the HMI430 offers an ideal control interface for equipment in fields as diverse as HVAC, dairy, packaging, pump control, commercial food processing, mining, health and fitness, and patient care. Early adopters have implemented HMI430 for a microbrewery bottling machine and leisure spa hydrotherapy tub control.

“Reduction of production costs while maintaining superior quality is an ongoing challenge for a microbrewery,” confirmed Simon Ross, of MicroBrewTech Ltd in New Zealand. “The HMI430 enabled me to control and coordinate multiple processes behind an interface that was easy to understand and use. The number and variety of I/O ports all coordinated with a simple multitasking interface enabled me as an application-focused developer to achieve much better efficiency and control. And when I ran into challenges, SPLat Controls offered exceptional customer support guiding me through development and product integration.”

The HMI430 uses a 120MHz ARM™ Cortex™-M4F processor with hardware floating point, onboard graphics control and 512KB of flash memory for program storage. The display is supported by 8MB of flash for images and fonts. A 16MB display buffer allows glitch free re-writes. The digital outputs can directly drive relays and solenoid valves up to 500mA at 24V, and the inputs are compatible with industrial NPN type sensors. The two analog inputs provide 12-bit resolution and can measure voltage, current or temperature. There is also a 0-10V, 10-bit analog output.

Integrated MultiTrack™ operating system

HMI430’s MultiTrack cooperative multitasking operating system

offers reliable, non-stop operation, free of hazards like resource locking and priority

inversion that can lead to unnecessary downtime. MultiTrack’s safe, easily understood environment enables OEMs to develop sophisticated real-time

applications tailored for small- and medium-business environments. A single unified application program operates both the control and the display

functions, ensuring that any updates to an OEM’s program only require a single download by the end user.

Communications and expansion interfaces

HMI430 offers one RS485 port and two TTL level serial ports, with built-in Modbus and the ability to implement custom protocols. A serial expansion port

supports a range of existing SPLat "Xwire" special function peripheral boards

such as pH measurement, Internet connectivity, data logging, and temperature

measurement. A new range of matching I/O expansion boards provides additional digital I/O, relays, and analog I/O, and can be linked together via

RS485 to create a distributed processing system.

Availability and pricing

The HMI430 can be ordered now in sample quantities from the SPLat Controls website.

Pricing starts at $329 1-off, with discounts for larger quantities. Customers can also download the free IDE, SPLat/PC, and find full product documentation

with a number of sample projects to get started.

Full programming service with or without ongoing program maintenance options are available. Plus, customers gain access to a clearly defined path to migrate to a more customized controller.

For more information, view the SPLat HMI430 video or visit http://www.splatco.com/hmi430_p1.htm

Contacts |

Images(To download hi res, left-click the thumbnail to display the full size file, then right-click that and and Save Image)

|

Other resources |

|

Media Contact:

Sales Contact:

|

|

Case study: Beer bottling machine (pdf) Case study: Luxury hydrotherapy tub (pdf) Power Point. Describes the whys and wherefores of our target market very clearly. |

SPLat Controls, the SPLat logo and MultiTrack are trademarks of SPLat Controls, Pty Ltd. All other product or service names are the property of their respective owners.

© 2014 SPLat Controls Pty Ltd