MicroBrewTech is a start-up located in the picturesque Victorian-era town of Oamaru in New Zealand's South Island. With the world-wide rise in the number of boutique- and

micro-breweries, the company's founder, Simon Ross saw a need for brewery equipment that would be affordable for small, high quality brewers.

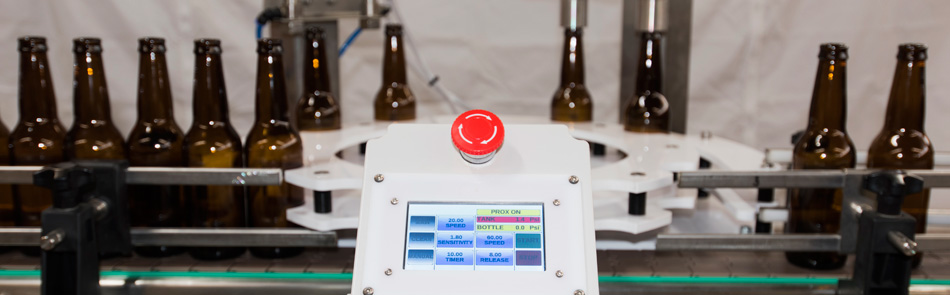

The first product Simon set out to design is a filler and capper that can fill 3600 bottles of beer a day.

MicroBrewTech is a start-up located in the picturesque Victorian-era town of Oamaru in New Zealand's South Island. With the world-wide rise in the number of boutique- and

micro-breweries, the company's founder, Simon Ross saw a need for brewery equipment that would be affordable for small, high quality brewers.

The first product Simon set out to design is a filler and capper that can fill 3600 bottles of beer a day.

When he started designing the machine, Simon, an experienced machine builder, had prior exposure to industrial PLC controls. It was therefore a natural choice for him to use a conventional micro PLC as the main control element. What he discovered, however, was that the lack of a rich operator interface was constraining his design, and adding a conventional HMI unit to the PLC would blow his budget out of the water. So he did some further research and discovered SPLat Controls, who pioneered embedded controllers with integral operator interfaces back in 1998. As luck would have it, SPLat were in the process of developing their first off the shelf controller with an integral colour touch screen, the HMI430, and they agreed to supply Simon a prototype unit for his development work. The resulting REV500 bottling machine leverages the HMI430's easily programmed touch screen to provide the operator flexible control over the machine's various functions and settings. It also helped Simon include a level of automation and adaptability that's quite unusual in a low cost machine, so small operators can quickly reconfigure for various products, and easily integrate other equipment such as labellers. Because the HMI430 was still under development, with scant documentation for the display functions, SPLat provided Simon with sample code snippets to get him going. Simon however quickly amplified on those examples, created his own custom graphics and produced his own attractive screen designs.

"At a purely rational level, the ability to have multiple screen layouts for different functions definitely improves the usability of the machine. But beyond that, even in a business investment the eye appeal will still be a factor. And having the colour screen makes the machine seem thoroughly up to date - which of course it is."

Simon Ross, MicroBrewTech